Hand trucks are an essential multipurpose device that can be used for nearly any application. With rugged construction and aluminum composition, a hand truck is a tool that will last for a long time. The heavy duty nature of the material allows for a hand truck to hold hundreds of pounds, which makes it perfect for anything from moving sound equipment to moving boxes of heavy materials.

The tough materials used in constructing a hand cart allow for it to last a long time, even with repeated and extended usage. While these carts are well-constructed, they are also lightweight and extremely portable, generally weighing in at less than fifty pounds. Hand carts have a wide body which allow for superb cart stability. Even off-balanced loads can be handled on a cart so long as care is taken during transportation.

Convertible hand trucks with rugged, pneumatic air filled wheels can be used on a vast range of terrain. These hand carts can be used upright for moving bulky items or for convenient storage. They can also be lowered and used for transportation of many different materials, with multiple options for handles. One type of handle system incorporates dual grips, which are especially useful for pushing the cart. Another type of handle system is a continuous handle, which is beneficial for applications that involve pulling a hand cart. There are many handle system variations that can be matched to any need. The conversion from two wheels to four wheels is extremely easy, as in the conversion from four wheels to two wheels.

Buycasters.com carries a wide selection of affordable hand trucks from top name brand Wesco. Find the hand truck perfect for your carrying needs today.

Tuesday, January 28, 2014

Tuesday, January 14, 2014

How to Choose Casters & Wheels

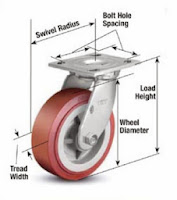

Moving furniture and heavy objects, from cabinets to industrial supplies, can be a heavy burden without wheels or casters. Casters include bearings, casings and wheels attached to a fastener to allow movement of heavy objects across a set distance. Whether you’re in need of casters for your business or your home, choosing casters takes the consideration of several factors, from possible weight loads to everyday versatility.

Here are some important things to remember when choosing casters:

Here are some important things to remember when choosing casters:

- Weight or Load Capacity - Before you decide on any caster based on material, diameter or attachment point, you have to determine the weight of what you’re trying to move. Each caster holds a maximum load capacity and this includes not only the object that you’re trying to move, but any cart or equipment weight that will also be the burden of the caster. Once you know the total weight of your load, you’ll be able to do divide that by the number of casters and wheels you’re using to find out the load capacity per wheel. Add more casters to heavy pieces to distribute the weight evenly and safely. Casters and wheels can fail and possibly injure you if not analyzed correctly for weight loads. Even when analyzed for proper load capacity, you’ll have to be cautious not to overload your casters. Try to move your load across an even surface at a steady, slow pace.

- Attachment - Two attachment strategies are available from most caster manufacturers. One type is better for movement whereas the other is better for larger, stable objects.

- Post/Stem casters use a long peg that fits directly into a machined orifice in the piece. A 2-inch chrome/gray rubber stem caster, for example, affixes to the object being moved to create a locking connection point. As you move around, the stem remains stable within the construction.

- Plate casters use screws to attach the fastener to the object's base.

- Wheel Type - Choose caster and wheel materials that match your strength and durability needs. As a cost saving tip, increasing the height and width of a caster and wheel will increase your load as long as you’re keeping your wheel materials consistent. Moving to a larger 10”x2” phenolic wheel from a smaller phenolic wheel will increase capacity, but moving to a 10”x2” Polyurethane wheel from a smaller phenolic wheel will not.

- Plastic is an inexpensive choice for lightweight applications since it is a softer material. For example, rolling a lightweight cart across a warehouse does not require a strong caster material.

- Select all steel wheels for heavy duty needs, such as moving heavy cargo loads on a cart. Phenolic wheels are also a stronger compound that may be beneficial in heavy duty moves.

- Office applications, where you need to protect the flooring from scuffs, require polyurethane or rubber casters. These soft materials keep the floor shining brightly, but they can’t handle the same heavy load capacity as a steel or phenolic wheel.

- Surfaces – In general, the larger the wheel diameter of your caster, the easier it roll across any surface. Anti-friction bearings will also help improve the smoothness of your ride. Of course, there are many different types of wheels and caster materials that are specially designed.

- If you have a slick floor surface, choose casters with specialized teeth. Typically applied to hard rubber materials, these locking teeth hold the wheels in place when you activate their mechanism.

- Wheels with soft rubber treads will help protect certain floors like softer tiles or hardwood floors commonly found in homes.

- If you need to increase load capacity across a softer floor, choose a Polyurethane tread.

- Regardless of your surface and wheel type, if you’re repetitive moving your load across the same path and surface, you will eventually see wear on the surface.

- Direction - Some of the objects you move need to be moved in a basic straight direction, including food carts. Other applications, such as electronic mobile cabinets, require precision movement with 360-degree casters. Swivel casters allow you to move the in almost any direction instantaneously. A 2-inch black/black poly stem caster is an elegant-looking wheel that blends in with black electronic cabinets for a professional appearance.

- Specialty Casters - You may have certain caster needs that are outside generic contours. For medical industries, look for anti-bacterial wheels to prevent germ spread throughout a building, such as on crash carts. Shock absorbent casters are also available for sensitive electronics, including medical instruments.

Subscribe to:

Posts (Atom)